Single Pole Sliding Contact Wire Installation Guide

Gantry crane power supply line installation - overhead installation

Installation method of single pole sliding contact wire for gantry crane

There are two ways to install the sliding contact wire of the outdoor gantry crane: the first is overhead installation, that is, erecting the pole(mast) or steel column beside the rail of the gantry crane, laying the track on the steel column, then welding the angle steel bracket of the sliding contact wire on the steel column, and then installing the sliding contact wire in the normal order. The second way is to adopt the trench type top edge installation method, dig a drainage ditch on one side of the gantry crane track, and the depth can be determined according to the actual situation. Then, weld or fix the angle steel bracket of the sliding contact line on the gantry crane track or track pressing plate, and then install according to the normal installation sequence of the sliding contact line.

Overhead installation

Single pole power line installation of gantry crane

Ground installation

Single pole power line installation of gantry crane

Single Conductor Slide Wire

Product Description

The single conductor slide wire is a new type of power supply system for mobile mechanical equipment. It is a safe, economical, reliable and widely used mobile transmission device, which can be combined at any level according to its own needs,Suspension installation is convenient, large output current, large distance between phases (high safety), fast running speed, smooth running, low noise and so on.

The conductor is made of specially formulated high-quality aluminum alloy profiles, and its outer sheath is made of special PVC material to prevent rain, dust, snow, The safety function of preventing electric shock. Simple structure, convenient installation and maintenance, widely used in power supply lines of mobile equipment such as mines, metallurgy, chemical industry, machinery, docks, freight yards, etc.

Features:

- It is safe and reliable, there is no risk of electric shock even if it is touched with fingers

- Energy saving and consumption reduction, using special formula aluminum alloy profiles as conductors; low resistance, which can greatly reduce power loss

- Sheath and accessories are universal

- Long service life, the conductor sheath is also made of unique material, which prolongs the service life of the single conductor slide wire.

- The collector can move in three-dimensional space, which can meet the uninterrupted power supply of power supply equipment; adopts double insulation design, safe and reliable work

- New materials, new technologies and new processes ensure that the products have high corrosion resistance, acid resistance, weather resistance, and safe and reliable working performance.

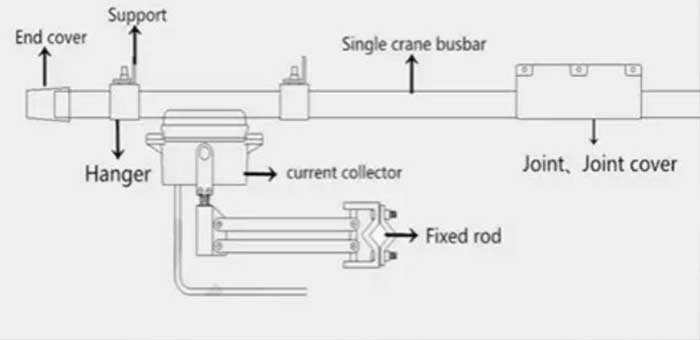

Crane power supply line accessories

Item | Accessories name | Installation requirements |

1 | single conductor slide wire | The slots of single conductor slide wire must be downward |

2 | Current collector | One or two sets of one device |

3 | Fixed rod | Same with Current collector |

4 | Support bracket | standard distance is 2 meters each |

5 | Hanger | standard distance is 2meters each |

6 | Joint,Joint cover | one of every six meters |

7 | End cover | Both ends of the single conductor slide wire |

Single conductor slide wire

Current collector and Fixed rod

Support bracket and hanger

Joint & Joint cover

End cover

Single conductor slide wire installation process

- Weld the support bracket to the supporting beam with an interval of 2m and a welding length of about 50mm.

- Put the hanger on the single conductor slide wire, the number of hangers required for each slide line is determined by the bracket.In generally, there are three hangers on a single conductor slide wire.

- Fix the joint on the single conductor slide wire, and each slide line only needs to install one joint.

- Install the single conductor slide wire on the bracket, connect the slide line joint straighten it, and tighten the buckle screws.

- Install the joint cover and End cover

- Fix the current collector on the mobile device through the fixed rod so that the current collector can run flexibly in the single conductor slide wire.

- The installation of the entire single conductor slide wire is completed, and then for the last inspection, we can turn on the power supply for trial operation.

Maintenance

Single conductor slide wire should be checked regularly. Because electrical equipment is the main production tool of every industrial and mining enterprise, a slight error will directly affect the production efficiency of the factory.

When checking the single conductor slide wire, check whether the joint is loose or disconnected.

When checking the current collector, check whether the movable part rotates flexibly, the brush is worn, etc. (These conditions will affect the conductive performance of the single conductor slide wire) On-site installation pictures

Single pole power supply line installation